FstaRockr Burns

Regular Contributor

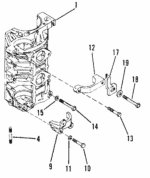

Hi everyone.. my first post here, and I just bought my first boat an hour ago.. killer deal (im hoping) on a rib with a mariner 60 - not sure what model, maybe someone can comment..I do rebuild bikes and cars and carbs.. so not unfamiliar with the mechanical bit - just new to outboards..

Anyway - what do i check before firing her up? Is there an achilles heel with these motors? We used the same model different HP on our family fishing boat when i was young - think we had 2 issues in 8 years..

Is a compression check one of them?

What else?

This is the motor - looks like there's hydraulic trim/tilt too yes?

Anyway - what do i check before firing her up? Is there an achilles heel with these motors? We used the same model different HP on our family fishing boat when i was young - think we had 2 issues in 8 years..

Is a compression check one of them?

What else?

This is the motor - looks like there's hydraulic trim/tilt too yes?