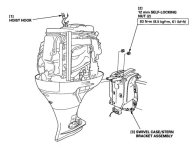

Alright, so I backed the rear quarter of the boat into the garage and got started before lunch today. I decided to remove the motor from the transom entirely to perform other maint in the comfort of the AC, which means I can work day or night - you don't work outdoors after 6pm here, the mosquitoes will carry you away. First order of business was disconnecting the control cables, main harness and battery cables. That was not much fun, but it's not too different from working on a modern car and I got through it. Next I still followed the manual's method of attaching the hoist to the lifting ring, removing the top two nuts, then removing the bottom two nuts. Pulling back on the wheeled engine hoist, all I could get was about 1/4" gap on the bottom bolts and maybe it wiggled 1/8" on the top studs. There's what appears to be a stainless shaft running right through the center of the mount frame (steering arm shaft) and into the lower unit. I don't see how it's possible to separate the motor from the mount frame with this in place, and it can't come out the top or bottom - unless I'm supposed to drop the lower unit too? Manual doesn't say!

So I broke down and removed the entire bracket from the transom and left it on the hoist in the garage. In retrospect that's much easier and will allow me to reseal the bolts because I didn't notice any silicone remnants and that's not a good thing. Additionally, removing the old steering bracket wouldn't have been possible with the bracket still on the transom, so it was going to happen anyway and I just didn't realize it.

Now it's in the garage but I've had a full day and will leave it to think about how to attack it next time. How the heck do I get that shaft out of the center of the mount frame? I was under the impression the mount frame was solid, not hollow.