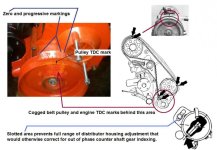

I've reassembled my engine and now need to set up the initial timing i.e. cam belt, crankshaft pulley etc and in order to do so correctly I need to find TDC on number one cylinder.

Research says to put my finger over the sparkplug hole and turn the engine until I feel the pressure. Sounds good, but no matter how I contort, I can't get a finger over that hole. I can stick a drinking straw in there and feel the piston rise, but that doesn't tell me if I'm on the compression stroke.

Is there some other method to visually determine TDC? Any help appreciated. Thanks.

Research says to put my finger over the sparkplug hole and turn the engine until I feel the pressure. Sounds good, but no matter how I contort, I can't get a finger over that hole. I can stick a drinking straw in there and feel the piston rise, but that doesn't tell me if I'm on the compression stroke.

Is there some other method to visually determine TDC? Any help appreciated. Thanks.