My 1984 Mercury 50 hp Outboard seems to run fine when starting and running in neutral, however when I try to accelerate beyond 6 mph the engine falls on its face and does not recover without backing off the throttle...

Tests I have performed and the results are as follows: (All of these test were performed at Cranking Speed. Not Running)

1. Compression test (Ft Lbs): #1=140, #2=150, #3=140, 4=140

2. Coils (Ohms): #1=.2, #2=.2, #3=.25, #4=.25

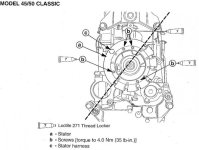

3. Stator (DVA): 218V

4. Trigger (DVA): 3.749V

5. Trigger (Ohms): Brn to Wht/Blk = 792 & Wht to Vio = 798

6. Verified All Plugs were firing as expected.

(Based on the information I have, the results above appear to be within range.)

Tune-ups:

1. Cleaned both Carbs.

2. Kitted both Carbs., with New Needles.

3. Adjusted Float Leaves.

4. Replaced All Plugs

Test I believe I still need to do:

1. All of the above tests with the Engine Running.

2. Check Timing.

3. Verify, with Timing Light, what cylinders are firing based on each plug wire.

With consideration of the results above, are there any specific tests that should be focused on more than any other to address this type of issue?

Thank you in advance for any expertise you may provide.

Tests I have performed and the results are as follows: (All of these test were performed at Cranking Speed. Not Running)

1. Compression test (Ft Lbs): #1=140, #2=150, #3=140, 4=140

2. Coils (Ohms): #1=.2, #2=.2, #3=.25, #4=.25

3. Stator (DVA): 218V

4. Trigger (DVA): 3.749V

5. Trigger (Ohms): Brn to Wht/Blk = 792 & Wht to Vio = 798

6. Verified All Plugs were firing as expected.

(Based on the information I have, the results above appear to be within range.)

Tune-ups:

1. Cleaned both Carbs.

2. Kitted both Carbs., with New Needles.

3. Adjusted Float Leaves.

4. Replaced All Plugs

Test I believe I still need to do:

1. All of the above tests with the Engine Running.

2. Check Timing.

3. Verify, with Timing Light, what cylinders are firing based on each plug wire.

With consideration of the results above, are there any specific tests that should be focused on more than any other to address this type of issue?

Thank you in advance for any expertise you may provide.

Last edited: