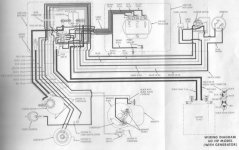

Hi All, I'm chasing a. New control box for this engine does anyone know where I can get this from?

Also my great shifter has way to much play in it anyone know how I can adjust as the control cable moves fully but doesn't engauge the gear as there is too much play ?

i also need a alternator or generator whatever you call it that changers the battery off the engine does anyone know if this engine came with one and if so where I can get it from?

any help would be appreciated ?

Also my great shifter has way to much play in it anyone know how I can adjust as the control cable moves fully but doesn't engauge the gear as there is too much play ?

i also need a alternator or generator whatever you call it that changers the battery off the engine does anyone know if this engine came with one and if so where I can get it from?

any help would be appreciated ?