View attachment 10295

The image is a picture of a Volvo 5Lt V8 fitted with SS integrated exhaust/risers.

The two blue pipes in the image are the pipes that I am talking about.

You're talking abut two the blue hoses, not pipes.... correct?

in this image they go to the two inlets to the SS manifolds.

Yes! This is the "spent" seawater path.

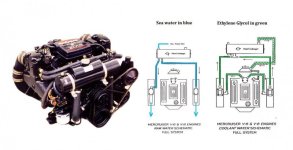

Whether the engine is raw water cooled or a Half CCS is installed, this path would be the same.

On my current engine they go to the CI exhaust manifolds.

When I fit the HE I intend to connect these pipes together via a "T" pipe and feed the water back to the HE.

Unless you're doing a Full System, this is "spent" seawater, and will enter and exit the exhaust system.

IOW, there is no returning water or coolant to the system from this location.

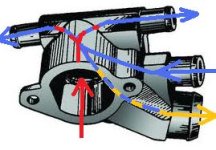

Be careful when you "T" or Split water flow.

Depending on which part of the system, this will require a "diverter style T or Y" ...... not a normal T fitting.

In the Volvo closed cooling system these outlet pipes from the thermostat housing do not exist.

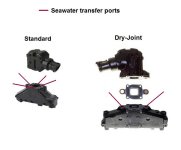

Correct! The Raw Water cooled engine thermostat housing incorporates a mixing chamber.

This style cannot be used for a Closed Cooling System.

(see image below)

I saw an image of the "T" pipe somewhere in an arctical on cooling , I believe it related to a Mercruiser but the water ciruit must surely be much the same for both makes.

You'll find that there are similarities.

Does your kit not include all parts?