Craig Bradley

New member

Hello all. Great site with great info.

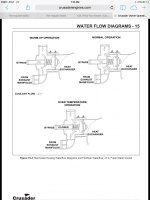

I have a 2003 crusader 8.1ho engine with 600 hours on it. Boat has only been in fresh water. I recently noticed the overflow bottle was completely full and coolant was spilled all over the place since the overflow bottle overflowed. I took off the heat exchanger cap and noticed the coolant was low as the coolant did not return to the heat exchanger as the engine was cooling. I returned the levels to normal. I ordered two new radiator caps. I tested the old cap and found it was fine. I still went ahead and replaced the cap. The boat runs fine around 2000rpm at that rpm the bottle will not overflow. But if I run the boat at cruise around 3600 rpm the overflow bottle starts filling and eventually overflows. I have also pressure tested the engine cold and found no leaks. The engine will hold pressure. I called crusader and they think the system is sucking air somewhere and that is driving the coolant out of the heat exchanger. I have looked down into the overflow bottle while it is filling and do not see bubbles. I have tightened all the hose clamps. I have checked the strength of the antifreeze and it seems to be at the correct 50/50 strength. Which is -30 degrees. The strength out of the gallon jug of prestone 50/50 antifreeze is -34. Oh and the engine does not overheat. I have a digital temp guage on a b and g engine and it reads about 160 at 2000rpm and 166 at 3600rpm.

i am out of ideas and am hoping someone has some ideas. Thank you in advance for your answers.

I have a 2003 crusader 8.1ho engine with 600 hours on it. Boat has only been in fresh water. I recently noticed the overflow bottle was completely full and coolant was spilled all over the place since the overflow bottle overflowed. I took off the heat exchanger cap and noticed the coolant was low as the coolant did not return to the heat exchanger as the engine was cooling. I returned the levels to normal. I ordered two new radiator caps. I tested the old cap and found it was fine. I still went ahead and replaced the cap. The boat runs fine around 2000rpm at that rpm the bottle will not overflow. But if I run the boat at cruise around 3600 rpm the overflow bottle starts filling and eventually overflows. I have also pressure tested the engine cold and found no leaks. The engine will hold pressure. I called crusader and they think the system is sucking air somewhere and that is driving the coolant out of the heat exchanger. I have looked down into the overflow bottle while it is filling and do not see bubbles. I have tightened all the hose clamps. I have checked the strength of the antifreeze and it seems to be at the correct 50/50 strength. Which is -30 degrees. The strength out of the gallon jug of prestone 50/50 antifreeze is -34. Oh and the engine does not overheat. I have a digital temp guage on a b and g engine and it reads about 160 at 2000rpm and 166 at 3600rpm.

i am out of ideas and am hoping someone has some ideas. Thank you in advance for your answers.