Scott Mosteller

Member

Hey friends! I am new here and wanted to see if you guys could help me out!

I just rebuilt my chevy 350 last year, she has about 10 hrs on it. Right when I rebuilt it, the alpha 1 drive blew up as well. SO, i put her in storage for 6 months and just waited till i had the funds and time to fix her. Finally, i got a new drive put on, and shes ready to romp!

I just installed a new temp gauge tonight, (didn't have one before) and when i backed her into the water at the launch ramp, i just left it attached to the truck. I jumped in and wanted to run it and see what she was doing. After 10 minutes or so, the temp gauge is reading 210 degrees at idle... a little high!!

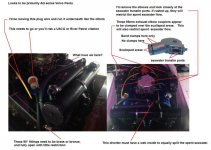

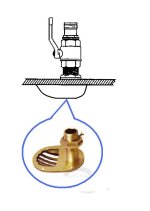

I checked the left exhaust riser and its real hot, the right one is semi hot. It is raw water cooled for the exhaust, and i have a heat exchanger for the engine cooling system. The heat exchanger is ALSO hot, REALLY hot. I just replaced the raw water impeller as well. So strange, the raw water inlet hose that connects to the impeller housing, was REALLY pinched, like real bad. I gassed it hard twice and im not sure what happened, but it fixed the hose and i think its flowing well again? something seems clogged or pinched cause its still hot and im lost for words right now.

I replaced everything when i did the engine rebuild. Water pump, exhaust headers, risers, etc. I didn't replace the heat exchanger though, do we think that this may be the problem? Maybe get it hot tanked or something?

Happy to answer any questions to help me get to the bottom of this! Shes so close i just need to finish up some of the kinks and she'll be rip rap!

Thanks friends, scott!

I just rebuilt my chevy 350 last year, she has about 10 hrs on it. Right when I rebuilt it, the alpha 1 drive blew up as well. SO, i put her in storage for 6 months and just waited till i had the funds and time to fix her. Finally, i got a new drive put on, and shes ready to romp!

I just installed a new temp gauge tonight, (didn't have one before) and when i backed her into the water at the launch ramp, i just left it attached to the truck. I jumped in and wanted to run it and see what she was doing. After 10 minutes or so, the temp gauge is reading 210 degrees at idle... a little high!!

I checked the left exhaust riser and its real hot, the right one is semi hot. It is raw water cooled for the exhaust, and i have a heat exchanger for the engine cooling system. The heat exchanger is ALSO hot, REALLY hot. I just replaced the raw water impeller as well. So strange, the raw water inlet hose that connects to the impeller housing, was REALLY pinched, like real bad. I gassed it hard twice and im not sure what happened, but it fixed the hose and i think its flowing well again? something seems clogged or pinched cause its still hot and im lost for words right now.

I replaced everything when i did the engine rebuild. Water pump, exhaust headers, risers, etc. I didn't replace the heat exchanger though, do we think that this may be the problem? Maybe get it hot tanked or something?

Happy to answer any questions to help me get to the bottom of this! Shes so close i just need to finish up some of the kinks and she'll be rip rap!

Thanks friends, scott!