coolbri70

Member

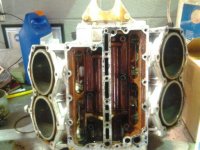

model 85995R, last time out my motor lost power and wouldn't idle, after discovering a dead cylinder and a water drip from the exhaust cover, I removed the cover and spotted damage when I looked in the ports, so I pulled the head and now I need to replace the piston, I wont be able to order a service manual for a couple weeks so am trying to pull the powerhead and not sure where to start. can I pull it on the transom or does it have to be removed from the boat? I am an auto mechanic so I'm not totally clueless but this is different and could use some direction till I can get my manual

Attachments

Last edited: