Was out on the lake the other day and my haul started to fill up with lake water.

Water was dripping from out of a hole from the lower flywheel housing ring gear bottom cover.

Not sure if a bolt fell out ,or this is a weep hole like you find on a water pump.

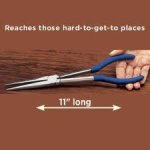

Anyways i tried to screw in a bolt ,but could not feel any threads,very hard to reach under .

I did take a piece of rubber and shove it in the hole so you can see it in the picture .

What is the hole ? Should there be a bolt in it ?

Below is a picture. You can see a bolt to the left and a piece rubber to the right.

I have a feeling my seal for the drive shaft is leaking.

Water was dripping from out of a hole from the lower flywheel housing ring gear bottom cover.

Not sure if a bolt fell out ,or this is a weep hole like you find on a water pump.

Anyways i tried to screw in a bolt ,but could not feel any threads,very hard to reach under .

I did take a piece of rubber and shove it in the hole so you can see it in the picture .

What is the hole ? Should there be a bolt in it ?

Below is a picture. You can see a bolt to the left and a piece rubber to the right.

I have a feeling my seal for the drive shaft is leaking.

Last edited: