Shark Bait

Member

Symptoms:

Ran (5100 RPM) for 45 minutes

Trolled (800-900 RPM) for 4 hours

Throttled up to head home and the engine would get to ~3000 RPM and then drop quickly back to 1000 for a few seconds and then up to 3000 and back.... The fuel ball is very soft even afte multiple pumps. Pumping it while running makes no difference.

Had to hold at 1200 RPM to keep it running steady. (2.5 hours to get back to the barn.. ugh)

Thoughts:

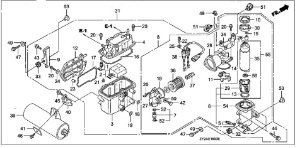

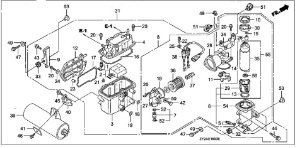

Fuel Screen inside Vapor Separator is clogged

The VST has never been removed and the engine has approsimately 400 hours.

Plan:

1 - Replace RACOR

2 - Replace Low Pressure Fuel Filter

3 - Disassemble and replace Fuel Screen in VST along with all O-Rings.

Anything else you guys can think of to start with?

Ran (5100 RPM) for 45 minutes

Trolled (800-900 RPM) for 4 hours

Throttled up to head home and the engine would get to ~3000 RPM and then drop quickly back to 1000 for a few seconds and then up to 3000 and back.... The fuel ball is very soft even afte multiple pumps. Pumping it while running makes no difference.

Had to hold at 1200 RPM to keep it running steady. (2.5 hours to get back to the barn.. ugh)

Thoughts:

Fuel Screen inside Vapor Separator is clogged

The VST has never been removed and the engine has approsimately 400 hours.

Plan:

1 - Replace RACOR

2 - Replace Low Pressure Fuel Filter

3 - Disassemble and replace Fuel Screen in VST along with all O-Rings.

Anything else you guys can think of to start with?