shieldshigh

New member

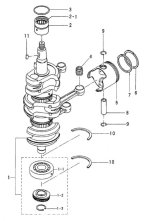

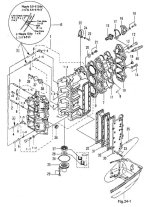

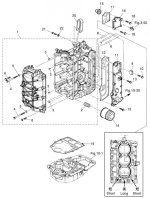

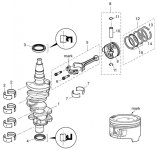

I have an NS40D motor on a boat that I just replaced the deck on. It was running great and then bogged down like it was out of gas. Continued to run rough - replaced fuel, fuel lines and filters and decarbed. Then it would start and run smooth - but I thought I heard a pinging. Put boat in water and suddenly was difficult to start but then ran well. It woudl reach 5000RPM+ as always, but pinging became knocking at 3,000 RPM and above so brought back in. Compression in top and bottom cylinders 120, middle cylinder 30. Pulled head and middle piston had been hitting head. Pulled inlet manifold assembly and I can push piston and connecting rod back and forth - bearing between connecting rod and crank is apparently destroyed. I looked in the parts catalog and don't even see the connecting rod or bearing as a seperate item - only the crank assembly.

Is there any hope here? I can't justify putting a ton of money into boat with kids getting ready to start college in a year or so.....

Is there any hope here? I can't justify putting a ton of money into boat with kids getting ready to start college in a year or so.....