Last fall I was running the boat near WOT. The motor had been running fine nearly all summer. (had to put a new coil in it) I noticed the rpm seem to fall off just a little bit and immediately looked down to find my overheat light on. Great. Pulled back the throttle and turned off the motor within a few seconds. Not sure how long the light was on for before I saw it. I usually make sure to check it at least every minute or so. I parked it, let it cool (it was very hot), and briefly tried starting it about 5 hours later. It fired right up but I noticed it sounded a little different and it looked like some of the exhaust was coming up behind the motor inside the cover. I didn't have time to deal with it so I winterized it, and reluctantly stored it for the winter. Now boating season has nearly arrived here in the UP of Michigan. I splashed it at the boat ramp yesterday and it started okay, seemed to be spitting the usual amount of water out of the exhaust, but was still smoking up between the motor and back cover. I did not take it out on the water as I did not want to cause further damage.

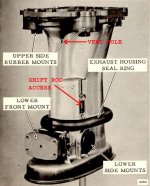

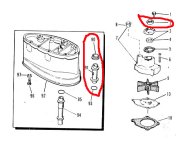

Here is my tentative plan. I will pull the lower unit and check impeller and key. I will look for damage to water uptake and exhaust as I suspect if there are any rubber seals they may have been damaged by overheating. For good measure I will likely put a new impeller in even though the current one is only 2 years old.

It is important to note that I let the boat idle for at least 15 mins yesterday and aside from a few small coughs it ran pretty well. No overheating as far as I could tell.

My question is what do I need to look for after a pretty severe overheating. Head gaskets? Ignition damage? What could be causing the exhaust issue? The motor is obviously not seized but I will check compression to make sure there is no piston damage as well. There is no visible damage to wiring etc.

Thanks for the help guys!!

Here is my tentative plan. I will pull the lower unit and check impeller and key. I will look for damage to water uptake and exhaust as I suspect if there are any rubber seals they may have been damaged by overheating. For good measure I will likely put a new impeller in even though the current one is only 2 years old.

It is important to note that I let the boat idle for at least 15 mins yesterday and aside from a few small coughs it ran pretty well. No overheating as far as I could tell.

My question is what do I need to look for after a pretty severe overheating. Head gaskets? Ignition damage? What could be causing the exhaust issue? The motor is obviously not seized but I will check compression to make sure there is no piston damage as well. There is no visible damage to wiring etc.

Thanks for the help guys!!