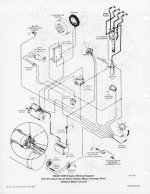

I have a 1981 Mercruiser 470 with 760 hours which I have owned for the past three years. It was not abused (but not maintained) when I got it, but over the past 3 seasons I have upgraded most of the recommended systems including, alternator, starter, riser, thermostat, cooling systems flushed and pertronix 1146a with 40k 3 ohm coil. The engine runs fine except after 45 minutes of run time the engine misses and backfires and will eventually die. I can run for half an hour no issues, only at forty five minutes. I'm confident in my fuel system because I ran an auxiliary outboard off the same tank. After lots of reading here, I suspect I may not have the pertronix kit wired to the coil incorrectly. The more i read the more confused I become. This is how it is wired now

negative has black from the pertronix and grey from the tach(?)

positive has red from the pertronix, purple with yellow stripe, and a more redish/brown shade of purple.

Both of these two purple wires are terminated together from the factory. the purple with yellow goes to a (solenoid looking thing) beside the starter and the more redish/brown shade of purple wire goes directly to the choke. I am not sure if this is wired correctly but it runs (for 45 minutes). I want to know do I simply cut the more redish/brown shade of purple wire away and carry on? Or, do I cut it out and have to wire in another regular wire between the choke and the coil. Or, do I have to remove more redish/brown shade of purple wire and run another wire from a keyed source to the positive side of coil? Man, I am not only confused - confusing too!

Thanks in advance teamcrush

negative has black from the pertronix and grey from the tach(?)

positive has red from the pertronix, purple with yellow stripe, and a more redish/brown shade of purple.

Both of these two purple wires are terminated together from the factory. the purple with yellow goes to a (solenoid looking thing) beside the starter and the more redish/brown shade of purple wire goes directly to the choke. I am not sure if this is wired correctly but it runs (for 45 minutes). I want to know do I simply cut the more redish/brown shade of purple wire away and carry on? Or, do I cut it out and have to wire in another regular wire between the choke and the coil. Or, do I have to remove more redish/brown shade of purple wire and run another wire from a keyed source to the positive side of coil? Man, I am not only confused - confusing too!

Thanks in advance teamcrush