I agree about keeping things on the thread...that's why we're all here.

For someone that might not have a lot of background in troubleshooting, you have pretty good instincts because yes, when checking resistance values or "ohm testing" components, they DO need to be "uncoupled" or isolated from the circuit that they may be a part of. Usually you can just unplug one wire of a two wire component, such as a coil, and that will effectively isolate it from everything else. However, if there is a grounded capacitor in the circuit it MUST be disconnected before testing or it will certainly skew the values.

Make sure that, if you are NOT working with an auto ranging, digital multimeter, that you select the proper "scale" on your meter prior to testing. This is perhaps the most common mistake beginners and the experienced alike make.

Also, when looking at resistance, temperature of the component can make a difference and must be taken into consideration. Heat will increase resistance and lack of heat will lower it. So, if your readings fall SLIGHTLY outside the range of specification, consider that most specs are published with a "given" temperature value of about 21C or 70f and a small discrepancy could be because of the part being left in the sun or in a cold room.

Here are the values I believe pertain to your case but if I leave anything out, let me know.

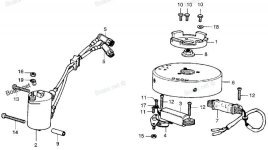

PRIMARY COIL...2.0 ohm. This is the coil under the flywheel that "charges" or powers the ignition coil through the breaker points.

CHARGING COIL...0.130 ohm. This is the other coil that MAY be under the flywheel for battery charging and would be connected to the rectifier under the hood. This has a "tolerance" listed of + or - 10%

If you find that either of these is outside the spec but is NOT OPEN, then I would not necessarily condemn the coil. As you read on, you will know why I say this.

IGNITION COIL PRIMARY WINDINGS...The big, black package with spark plug wires coming out of it. Here's where I need to go over a few things due to "discrepancies" that seem to exist between what is published in the HONDA service manual of that era and what I and others have empirically measured from "working coils" with no apparent defects.

The book says: 0.58 ohm with a tolerance of + or - 10%

I have measured a couple of operational coils and I believe the spec should be 1.5 ohm for a breaker point ignition coil.

And, for conversation sake, I have measured CDI ignition coils at 0.8 ohm.

So, as you can see, all the coils I have personally measured THAT WERE ON RUNNING OUTBOARDS fall well outside the published data from Honda. This doesn't mean that they are wrong and I am right but I wanted to make sure you have the whole story. NOW, We will see what YOU come up with.

IGNITION COIL SECONDARY RESISTANCE VALUES. Here again, we have a conflict with what is published in the Honda service manual and what I and others have ACTUALLY measured using good technique and accurate test equipment.

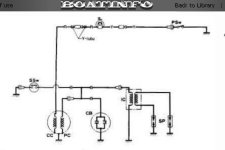

To measure secondary resistance you insert one probe into one spark plug boot and the other probe into the other spark plug boot. Thus, you are measuring the total resistance of both spark plug wires in series with the coil secondary winding.

The published spec from Honda is: 8k (8,000) ohm. with a tolerance of + or - 20%.... Remember to set your scale!

What we have ACTUALLY measured in the field: 31.5k (31,500) ohm.... Remember your scale.

Again, it is plain to see that the published values and what I physically see on WORKING COILS is WAY different.

Finally, we get to the condenser (capacitor)

Honda spec.....0.24mfd. (microfarad)

I have measured a few with my little old cap checker and get anywhere from .22mfd to .36 mfd. I think that if you have a condenser that is around .20mfd to .40mfd you are MAYBE ok. I say MAYBE because I don't know for sure and I'm no electrical engineer. It just seems that these babies will run if "close enough" so if the cap isn't open or isn't shorted to ground, then it will PROBABLY get you there.

Let me know if you need anything else and good luck.