hi

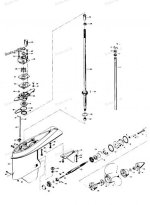

i have a 115 hp i pulled out the lower end to replace the water pump and i couldnt get the lower end back up i got told it needs to have the spline seal removed so i used a screw attached to a bar and even tried a scribber attached to the bar to pull out i dont feel the rubber in it, but i guess poking up there a metal O ring that is like a spring came out i guess that holds a rubber up? how i gonna get that back up

as i try to shove the lower end up but it wont go in the splines

let me guess i have to take the head off??? and if so whats the steps to remove it

and the model i have is

[h=1]1159B8B[/h]

i have a 115 hp i pulled out the lower end to replace the water pump and i couldnt get the lower end back up i got told it needs to have the spline seal removed so i used a screw attached to a bar and even tried a scribber attached to the bar to pull out i dont feel the rubber in it, but i guess poking up there a metal O ring that is like a spring came out i guess that holds a rubber up? how i gonna get that back up

as i try to shove the lower end up but it wont go in the splines

let me guess i have to take the head off??? and if so whats the steps to remove it

and the model i have is

[h=1]1159B8B[/h]