Hi guys, first time posting on your forum searching for suggestions / answers to my problem.

I have read numerous thread about a problem similar / same as mine but no one has come back on and posted if they fixed / repaired the problem and what they found !!!

In brief: Bayliner 245 2004 model with 5.0L Carby,

Drive: Alpha 1 leg, Prop: 4 blade 15 x 16 Pitch

Hrs: 120

Recently purchased boat, had it out on the water 3 times (Salt water ) each time out was seeing @ W.O.T 60km @ 4700Rpm.

4th time out was in shallow water at the boat ramp prop bottomed out and engine stalled.

Started boat and went up river, noticed a slight vibration coming thru the floor and interference on the fish finder screen. Stopped the boat and inspected the prop, no surprise had slightly bent 2 blades.

Took off up river opened up the throttle to maximum throttle and the engine would not Rev past 3200 Rpm / Speed 21kms top speed. Oil pressure 40Psi, Temp gauge 170 deg.

No engine miss or back firing, engine was purring from idle right thru to 3200rpm

This thing would not get on the plane anymore.

Loaded boat up on the trailer, headed home, flushed the engine and whilst on the muffs it Revved out to 5000Rpm and bounced off the limiter under no load.

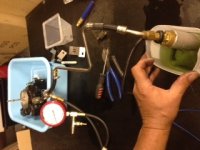

Repairs carried out:

Replaced prop, took boat out for another run, vibration had done but my W.O.T issue was still there.

Compression test: 175 - 185 Psi

Replaced Ignition coil and coil lead, rest of leads had between 4000 to 6000 ohms.

Removed exhaust manifolds & Risers to check for sand or blockages, all checked out clear.

Replaced exhaust flappers as one had half missing.

Checked Engine base timing 8 Deg with purple terminal shorted.

Swapped Carby with a mate who has the same model boat & no issues with his boat.

Checked fuel pressure 6 Psi

Took boat out for another run after doing the above repairs & checks and its exactly the same, problem is still there.

Any help would be appreciated.....

I have read numerous thread about a problem similar / same as mine but no one has come back on and posted if they fixed / repaired the problem and what they found !!!

In brief: Bayliner 245 2004 model with 5.0L Carby,

Drive: Alpha 1 leg, Prop: 4 blade 15 x 16 Pitch

Hrs: 120

Recently purchased boat, had it out on the water 3 times (Salt water ) each time out was seeing @ W.O.T 60km @ 4700Rpm.

4th time out was in shallow water at the boat ramp prop bottomed out and engine stalled.

Started boat and went up river, noticed a slight vibration coming thru the floor and interference on the fish finder screen. Stopped the boat and inspected the prop, no surprise had slightly bent 2 blades.

Took off up river opened up the throttle to maximum throttle and the engine would not Rev past 3200 Rpm / Speed 21kms top speed. Oil pressure 40Psi, Temp gauge 170 deg.

No engine miss or back firing, engine was purring from idle right thru to 3200rpm

This thing would not get on the plane anymore.

Loaded boat up on the trailer, headed home, flushed the engine and whilst on the muffs it Revved out to 5000Rpm and bounced off the limiter under no load.

Repairs carried out:

Replaced prop, took boat out for another run, vibration had done but my W.O.T issue was still there.

Compression test: 175 - 185 Psi

Replaced Ignition coil and coil lead, rest of leads had between 4000 to 6000 ohms.

Removed exhaust manifolds & Risers to check for sand or blockages, all checked out clear.

Replaced exhaust flappers as one had half missing.

Checked Engine base timing 8 Deg with purple terminal shorted.

Swapped Carby with a mate who has the same model boat & no issues with his boat.

Checked fuel pressure 6 Psi

Took boat out for another run after doing the above repairs & checks and its exactly the same, problem is still there.

Any help would be appreciated.....