jim18611865

Regular Contributor

http://www.marineengine.com/boat-forum/showthread.php?412328-1989-25HP-Carb-rebuild

Link to last thread for reference.

Compression is 89 each cylinder, spark is a nice strong blue over 1/2".

Carb and fuel pump rebuilt. Reed was broken and wrong gasket was installed.

I got it on the lake Saturday, but it runs really rough. It is sputtering and the more throttle the rougher it gets. It does stay running on its own now.

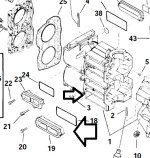

In my mind the timing must be way off, because the throttle lever must be adjusted so the throttle cam to roller looks like it is at 1/2 throttle. If adjusted where it should be it won't start. This is the way I received it. Manual says to start the timing adjustment at WOT, but there is no way I would get to WOT, nor would it be safe. I did get to about 1/2 throttle, but the more throttle, the more that engine jumps. It is loud too. I was running with the cowling off.

Any suggestions as to where to start next?

Thanks

Jim

Link to last thread for reference.

Compression is 89 each cylinder, spark is a nice strong blue over 1/2".

Carb and fuel pump rebuilt. Reed was broken and wrong gasket was installed.

I got it on the lake Saturday, but it runs really rough. It is sputtering and the more throttle the rougher it gets. It does stay running on its own now.

In my mind the timing must be way off, because the throttle lever must be adjusted so the throttle cam to roller looks like it is at 1/2 throttle. If adjusted where it should be it won't start. This is the way I received it. Manual says to start the timing adjustment at WOT, but there is no way I would get to WOT, nor would it be safe. I did get to about 1/2 throttle, but the more throttle, the more that engine jumps. It is loud too. I was running with the cowling off.

Any suggestions as to where to start next?

Thanks

Jim