ship wreck

Contributing Member

New to me 140 in my sig. It has a lot of junk built up on the outside of the exhaust housing. This was accompanied by black goo in the transom of the boat it came off of. I assumed the mess in the transom was gunked up water leaking out when the motor was tilted all the way up for transit. There is no junk in the bottom of the inside of the cowl.

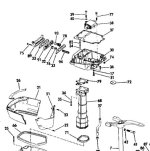

I have not run the motor other than for a short time so I have not looked for a leak. I'm hesitant to run it much until I go through the carbs as this motor sat for several months and it does not run "right" on the muffs. My main question is if this is a leak can I replace the gaskets on the inner housings without pulling the power head. It would seem I could get at it all with the gear case removed but wanted to know for sure. I'm ordering a water pump and carb kits and was going to buy the three exhaust housing gaskets as well but if I need to pull the power head I'm going to need more gaskets.

I have not run the motor other than for a short time so I have not looked for a leak. I'm hesitant to run it much until I go through the carbs as this motor sat for several months and it does not run "right" on the muffs. My main question is if this is a leak can I replace the gaskets on the inner housings without pulling the power head. It would seem I could get at it all with the gear case removed but wanted to know for sure. I'm ordering a water pump and carb kits and was going to buy the three exhaust housing gaskets as well but if I need to pull the power head I'm going to need more gaskets.