Perhaps try another zirk fitting, or try another grease gun.

How long since these have replaced?

Bearing crosses in a Marine Stern Drive application do not typically articulate to the same degree as car/truck bearing crosses do.

They also do not see any coast time, and the same side of the trunion is always under load.

This often equates to the bering cap and trunion surfaces being more "point loaded", causing them to wear more quickly than their automotive counter-parts.

If they are worn from point loading, no amount of new grease is going to save them.

I'd suggest removing one, and looking at the trunion bearing surfaces.

If bad, I'd replace them.

If OK, and if you do not want to replace them, reinstall 90* from the original indexing.

Don't flip it around.... simply just index them 90*.

This will put the load on the opposite side of the trunions.

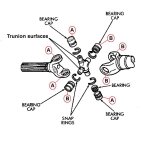

IOW, re-install with trunions and bearing caps A into yoke bearing cap bores B ... and with with trunions and bearing caps B into yoke bearing cap bores A.

(this a single bearing cross arrangement, but it will apply to your double)

Edit:

BTW, if the KC uses the same bearing cross as the early Merc's and Volvo Pentas, this will be a Spicer 5-1306X.

High quality, has the zirk in the apex of the cross, and you can buy these for about $14 each if you go to a 4WD Off Road shop, or a Truck Drvie Train component specialty shop.

These are an old Chrysler auto application but are still used in many applications today.