pugetsounder

Advanced Contributor

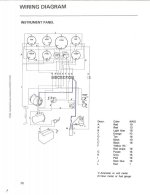

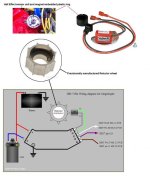

I've got a head scratcher. 1981 AQ120B with Hot-Spark Ignitor. I've noticed in the past year my ignition timing moves. Not all at once but from one or two trips out to the next. Once the timing is set, the boats starts easy, idles great, revs like it should. Get great gas mileage too. Then after a couple of trips out I notice harder starting and lots of pinging. Timing is off, I reset the timing and again everything is great til a couple of trips out. Once it was so far out I had to move the dizzy one tooth. But once it was set again it ran great. Weird!

In October I did a light winterizating on the boat, motor, and outdrive hoping to start it up once a month and warm everything up. Last christmas week it started up and idled no problem. This past weekend I could not get the thing to start. It will turn over and spit and sputter. I tried starting fluid with no success. I suspect it's out of time again severely this time. I will diagnose everything this coming weekend if I get time but I am wondering what are certain things to check? I know the timing belt is spot on. I know the distibutor is good and tight, no slop. The rotor and cap are in good shape. I suspect the Hot-Spark but I want to make sure I've checked everything else first before I call and try and get a warranty replacement. The Hot-Spark is only 1 year old and there is a 3 year warranty. Anybody hear of anything like this?

In October I did a light winterizating on the boat, motor, and outdrive hoping to start it up once a month and warm everything up. Last christmas week it started up and idled no problem. This past weekend I could not get the thing to start. It will turn over and spit and sputter. I tried starting fluid with no success. I suspect it's out of time again severely this time. I will diagnose everything this coming weekend if I get time but I am wondering what are certain things to check? I know the timing belt is spot on. I know the distibutor is good and tight, no slop. The rotor and cap are in good shape. I suspect the Hot-Spark but I want to make sure I've checked everything else first before I call and try and get a warranty replacement. The Hot-Spark is only 1 year old and there is a 3 year warranty. Anybody hear of anything like this?