I am not sure what the functional difference is with the front flywheel setup and the standard setup.

I am still hoping I can use these in my boat, but maybe I am missing something.

I may not be following you..... I don't know if you are missing anything.... but I think that we are missing some information from you.

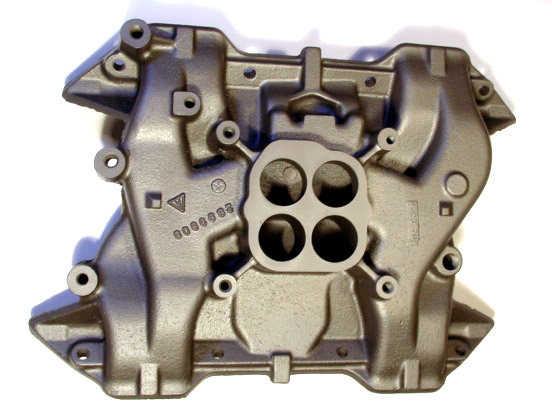

- Are your engines now Flywheel Facing Forward with Front Crankshaft drives aiming towards the stern....., like shown with the 383 photo????

- Or, are they Flywheel Facing Forward with Flywheel end V-Drive transmissions????

- Or, are your engines now Flywheel Facing the Stern, with Flywheel end transmissions????

Which ever the case, there will be critical engine/shaft alignment, but I suppose no different from any other re-power.

There are quite a few I/B guys here that can explain the procedure to you.

**********

My boat came originally equipped (in 1964) with Gray Marine 350's and (I am told) velvet drives. I am assuming this was a conventional rear flywheel setup. These front-flywheel engines seem like they will fit... mounting pattern etc is very close... they came with velvet drive gears (2.57:1 reduction).

Other than looking rather odd,

I don't believe that these Chrysler 383's are considered to be "front flywheel" engines. I think that you'll find that these are "Flywheel Facing Forward <slash> front crankshaft drive" engines, or what some call the

Goofy Chris Craft installation.

I believe that they chose the FFF/Front Crank drive in order to keep the prop shafts low without exaggerating the prop shaft angle. With the Flywheel towards the stern, the large flywheel diameter prevents the center line of crankshaft from being low in the hull.

When the engine was flipped around, now the center line of the crankshaft is closer to the hull.

Here's an old SBC 327Q installation....... it looks like it's sitting in the engine bay conventionally, but it is NOT.

The 327Q is a SBC. The ignition distributor is at the rear of the engine, even though this end faces the Bow of the boat.

The transmission is being driven by the front engine crankshaft, even though this end now faces the Stern of the boat.

I told ya........, Goofy, isn't it???

Something like this Walters V-drive..........

..... or this B/W V-drive may have solved the problem..... but I'm not sure what year drives like these become available.

In terms of being conventional, I'd say Industry Standard would be Flywheel AFT,

like in this simple illustration, or in

this stern drive illustration......... or Forward Facing Flywheel engines w/ V-Drives

like in this simple illustration.

These Chrysler 383's are not set up for any of the above installations, because they are driving the transmissions from the front crankshaft area...

not the Flywheel Ends.

Oddly enough, a conventional Flywheel End transmission drive for a Starboard RH Reverse engine, may become a Port RH Reverse engine with non-reversing V-Drive transmission.

Both rear of engines would still be the flywheel ends.... they just simply face towards the bow, instead of the stern.

NOTE: this changes nothing to the means of determining engine rotation or front/rear of engine.

Front is front/rear is rear just like if these were car or truck engines.

You will need to determine the rotation of your existing engines in order to know if these Chrysler engines will work for you.

*******************

Here's a conventional shaft drive installation (below)..... flywheels are facing the stern where the transmissions drive the prop shafts.

(those Chrysler 383 installations would have been opposite of this)

Look at the notation regarding rotation and the circle/arrows.

Although correct, this is not the industry standard means of determining rotation.

Standard means would be as though

viewed from the flywheel end ......... such as

this Standard LH rotation engine........ or this

Reverse RH rotation engine.

Top of image = front of engine.

Bottom of image = flywheel end.

The circle arrows are somewhat misleading unless we read the print carefully.

*************************

Here's another that can be confusing (below).

This should actually read;

"always view engines from the flywheel end" to clarify the Forward Facing Flywheel/Front Crankshaft drive engines (the Goofy ChrisCraft)...... otherwise this notation would be correct.

Sorry to get so far off into rotation, but sooner or later you'll need to determine this.

.