Hello all! I'm new to this great site and hope to contribute but right now need help getting my Skipjack 20 back in the water

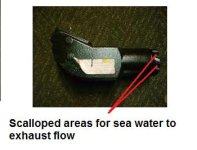

Some background info - "Finatic" is a 1984 Skipjack 20 Open designed by the legendary Jack Cole. She's powered by a raw-water cooled VP AQ260 with AQ280 Outdrive which have seen only 1500 total hours of use divided about 50-50 between Salt & Fresh water. Motor was professionally rebuilt at 1100 hours when pulled to replace a rusting oil pan. Outdrive was R&R'd at the same time due to water intrusion from a damaged bellows. Parts very recently replaced include new Raw-water pump, Water neck connection on drive, Thermostat, and Exhaust manifolds & risers.

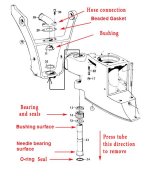

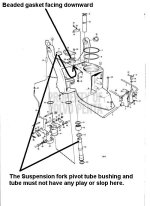

Overheat only occurs when boat gets up on plane, temps rise slowly from 160 to about 180-190 then spiking to 210 or so when throttled back and down off plane before slowly cooling back to 160. I removed the water neck connector thinking it wasn't sealing properly and found the gasket underneath was chewed up on one side of the o-ring like edge. Also, with the water connector removed, when you grab the lower unit and try to wiggle it, the tube (pivot tube?) underneath where the water connector mounts has considerable movement.

Is this movement the root cause of my overheat?

Some background info - "Finatic" is a 1984 Skipjack 20 Open designed by the legendary Jack Cole. She's powered by a raw-water cooled VP AQ260 with AQ280 Outdrive which have seen only 1500 total hours of use divided about 50-50 between Salt & Fresh water. Motor was professionally rebuilt at 1100 hours when pulled to replace a rusting oil pan. Outdrive was R&R'd at the same time due to water intrusion from a damaged bellows. Parts very recently replaced include new Raw-water pump, Water neck connection on drive, Thermostat, and Exhaust manifolds & risers.

Overheat only occurs when boat gets up on plane, temps rise slowly from 160 to about 180-190 then spiking to 210 or so when throttled back and down off plane before slowly cooling back to 160. I removed the water neck connector thinking it wasn't sealing properly and found the gasket underneath was chewed up on one side of the o-ring like edge. Also, with the water connector removed, when you grab the lower unit and try to wiggle it, the tube (pivot tube?) underneath where the water connector mounts has considerable movement.

Is this movement the root cause of my overheat?