I searched the forum for this topic, but only found topics relating to removal of carrier bearing not installation.

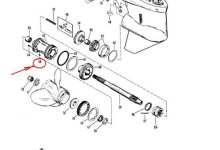

My son and I are working on a (1987) Mariner 115hp outboard, the original carrier bearing was cracked at the two tabs that bolt to the LU. That carrier bearing came out without any problems, but I'm having trouble getting the replacement back in (it is the correct/identical part). We can get it almost all the way in, but it's not seating ... about 3/16 - 1/8" left before it mates up to the LC.

Is there a trade secret to getting the carrier bearing to seat all the way? We've already gone through one replacement, breaking the tabs in the identical place by torqueing the nuts down too much ...

The shift cam seems to be working properly.

Everything is intact, I can feel the spring engage when we insert the assembly, but it just won't seat all the way.

any help on this would be greatly appreciated.

-Jay

Last edited: