You can use that mark to see if you are advancing just make a mark on the timing cover you can line the mark on the damper up to and watch the marks as you increase rpms the advance should be smooth with engine rpm gain. If you can get a good angle you can make your own scale on the damper pully using a protractor and a sharp yellow crayon, the mark on the damper being TDC go 45 degrees in both directions and mark every 5 degrees in between then you can estimate pretty close how far your dizzy is advancing from a idle to all in. Look at engine rpm when the advance stops moving.

I agree! This needs to be done.

Here is a simple method for transfering full scale markings (0* to approx 30* or 35*) to a harmonic balancer when the outside diameter is known.

For accuracy, make each new mark in 5* increments using the balancer TDC mark each time.

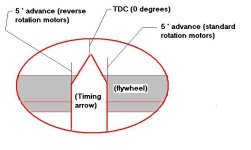

In post #20, Tahoerover noted that the flywheel cover should offer the corresponding TDC marks for 2.5, 5, 7.5 and 10 degrees.

If this is so on YOUR engine, then this may be the better location for checking your ignition advance.

Or.... bring this flywheel mark around to TDC (does not matter which stroke it is on), and transfer a new mark at the front area that corresponds with the harmonic balancer TDC mark.

Now you'll have two options.

***********************************

BTW, Tahoerover asked me earlier why I could not make a curve from the Chrysler numbers.

During the previous

"M440X timing" thread from November last year. I did attempt to plot out Chrysler's specs.... of which appear to be as goofy as the 318 specs!

Below is what the OEM 440 Chrysler specs look like when a curve is attempted to be plotted out. (blue graph line)

The heavy black line is a suggested curve for the GM Marine Engines.

(I simply over-laid this onto an existing curve in order to show the difference and the ramp up aggressiveness, of which would be dangerous, IMO)

As usual, this is showing mechanical advance only, and is minus BASE advance (at the vertical scale).

No one else bothered to do this, but you are certainly welcome to.

I'd like to see what the 318 numbers look like.

Jfreeman, we're now 77 posts into your thread. It's high time to ask you to do the work.

Throw your timing light on your engine, and strobe #1 cylinder.

Plot this out as per what Greasemonkey suggested earlier.

Post the results, and we can take it from there.

Meanwhile, if any member can come up with an OEM Chrysler Marine Corp ignition timing spec.... and I mean a useful curve (not simply BASE)....... that would be excellent!

.