Like said, I do not work on these, but I am very familiar with the cone clutch and it's adjustment.

See Stuart Hastings web site.

Stuart may explain his procedure for this adjustment.... I don't know.

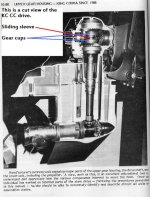

NOTE: this would be for the King Cobra Cone Clutch drive, not the KC Dog Clutch drive.

With most any cable control whereby there are two positions plus a neutral, the primary goal is to achieve absolute neutral, and work from there. Farm equipment, marine, garden tractor.... it's all pretty much the same.

Any over-travel should be divided equally, but again favoring the neutral position at both the selector and the throttle/shift unit.

The shift mechanism eccentric piston will be detent oriented, meaning that neutral will be when the piston sits at rest in the neutral detent.

I would begin there, and adjust the cable barrel fittings to just slide easily into position at both the eccentric piston and the shift unit.

Key point to note also, will be that any single lever Throttle/Shift unit is in harmony with itself, in that a full shift is achieved prior to any throttle operation. The single lever throttle/shift unit must be working correctly.... period!

Now make a full shift into FWD.

Remove the barrel fitting, and check for over-travel.

(this is at the drive, not the shift unit)

Now make a full shift into REV.

Remove the barrel fitting, and again check for over-travel.

Divide any over-travel (past full FWD or REV engagement) equally.

Now go back to neutral, again remove the barrel fitting, and see if it gently fits back into the gear selector arm.

With a single lever control, you should see full gear engagement prior to any throttle operation.

.