dogsharks38

Regular Contributor

Hello all,

I'm Paul from the ChrisCraftCommander.com web site and our membership frequently sources MarineEngine.com for help, so I would like to share some info back with you all here.

I have converted my 327F Chris Craft motor (on a 20' runabout, 1966 vintage) to the #1409 and it runs great. The 1409 is a 600 cfm carb and it is acutually thought of as "too big" for a 327, but in practice all I can say is the motor just runs great with it. Here are a couple photos.

This is what I started with, and now you can see why I wanted a new carb. The inside did not look any better.

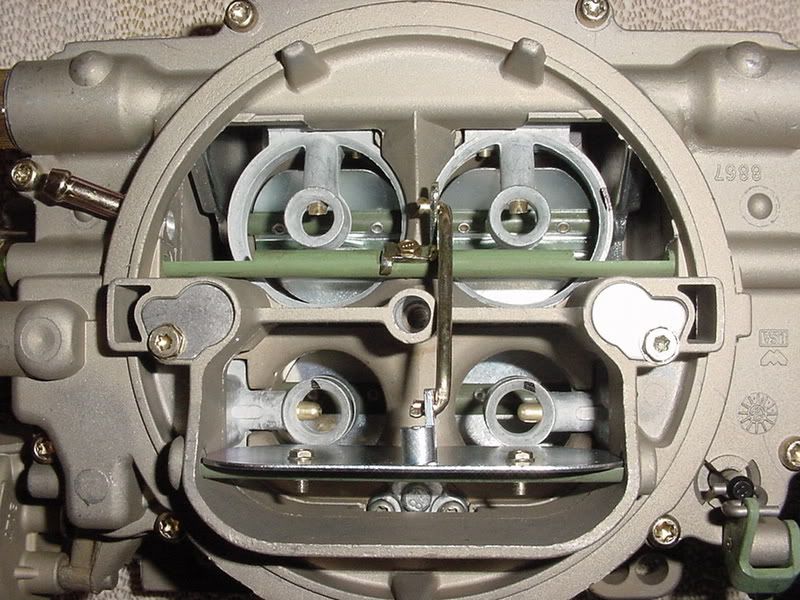

The new #1409 sure looked a lot nicer inside, and I am glad I did not have to spend ANY time trying to rebuild that old carb.

In this photo above you can start to see an issue.* There is a crankcase breather on the left that will allow fumes to be sucked into the flame arrestor, but that tube on the right is connected to a PCV system and this carb won't accommodate this feature.* On the Carter AFB from which this new Weber built Edelbrock #1409 was cloned, there is a vac port especially FOR the PCV system.* In a PCV system if it is hooked up properly you can get the idle down nicely and if you pull the hose off the engine will speed up, and this shows that the PCV is working properly.*

So now just because it seems I need to do this before I forget...............here is some data from the Carter 625 for the record here.

Here are the specs on the original Chris Craft Carter AFB

Original Equipment Chris Craft Carter AFB specifications (427 Ford)

Carb ID number is 4157 S

This is a 625 CFM unit.

Primary jet is .1015

Secondary jet is .086

Metering Rods are two step, first step (power) is .055, and the

second (cruise rod) is .061

You can almost buy the exact same carb

from Carter, with improvements of course (hey, they have learned a

thing or two about carbs in the last 35 years, no longer use leather,

for instance). Edelbrock has a 600 CFM unit that matches up pretty close, but

Carter has a 625 marine which is even closer, but the jets on both of

these are a tad different than the ones selected for the 427 Ford..

By comparison, the (generic) marine Edelbrock 600

Primary jet: .098

Secondary: .101

Metering rods: .068 x .047

So I noticed there is a place to drill the #1409 to accept a PCV valve just like the ones on the original CC motors, and I found this marvelous thread here on the MarineEngine.com site with photos and specs how to do this.

http://www.marineengine.com/boat-forum/showthread.php?252498-Edelbrock-1409-PVC-Fitting-Install

This is a wonderful thread and I want to share it on my own web site to help people, with due reference back to this site of course.

So in any case today I called Edelbrock for some assistance (doing my homework, I didn't want to drill a $360 carb just yet without wondering if they had a PDF they could send me showing more info).**

Well I am disappointed today, got a guy in the carb tech department who thought the marine carb had a soft plug and all I had to do was pull it out.

When I politely advised him that due to his comment, it suggested he had not seen a #1409 marine carb lately, he decided to get some help.............then after two more holding patterns I finally got the "carb department supervisor".

This guy was polite and he deserves due credit for this. He offered nothing in the way of tech assistance or help, however.

He said "We sell about 3500 of these per year and we get about 3 calls per year on this subject".

He claimed the USCG would not allow them to build a carb with a pcv system port, and this may be true, but I am unwilling to argue the point. It seems a pcv system is

a requirement on an inboard engine, because we can not be dumping corrosive and explosive petroleum mist into an enclosed compartment like that.

Just putting a vent near the carb so it sucks in any fumes is a very poor substitute for an actual POSITIVE crankcase vent system.

The petroleum laden mist is caustic and it can even be explosive.

I mentioned that Edelbrock didn't drill the carb but they put a dimple there where it was supposed to be drilled, but they would not help a guy who wanted (and needed) to drill one to meet functional needs.

I got no sympathy (or help).

All I got was the company liability management chapter and verse.

He said his hands were tied due to the liability.

This may be true, but it is also a little sad.

We're basically on our own.

So in any case, the #1409 works just great on my 327F, I am installing one on a custom 427 FE now, and I plan to install two on my twin engine 427-powered 1966 38 Commander in the near future.

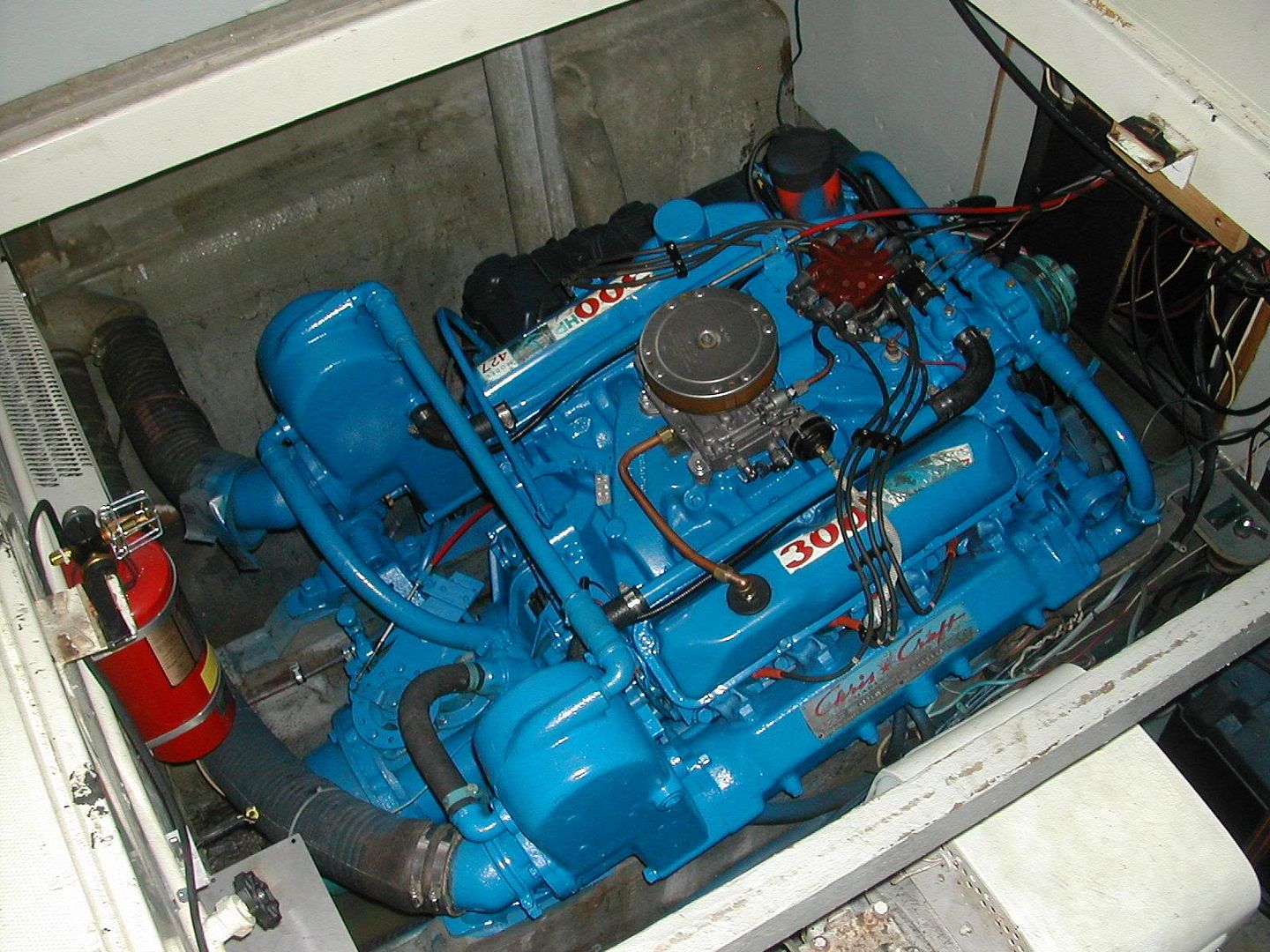

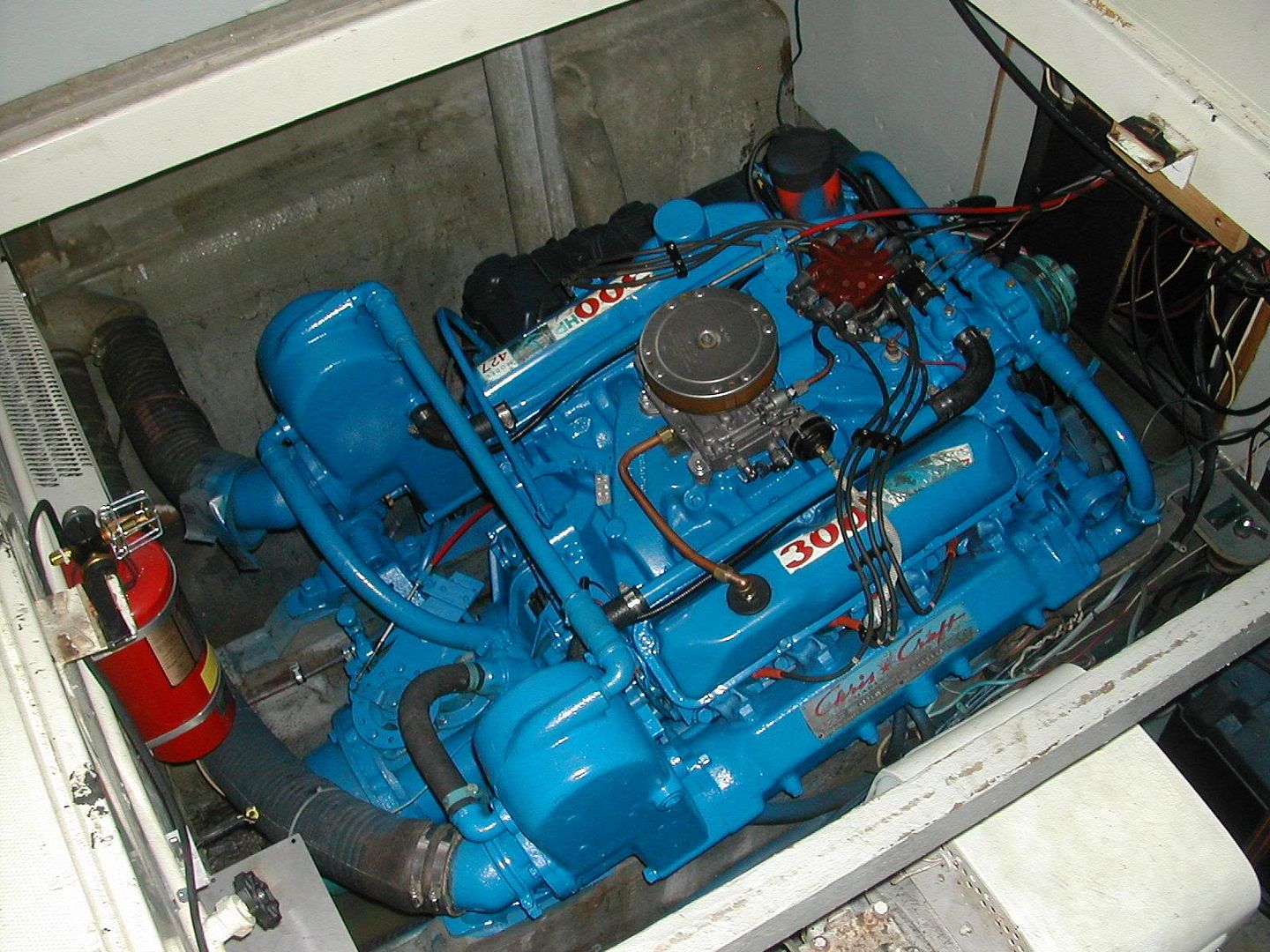

Here is a photo of the 327 running nicely, proof the 600 cfm carb works well on a small block motor.

Yeah it's running good but look at that home-made PCV system.

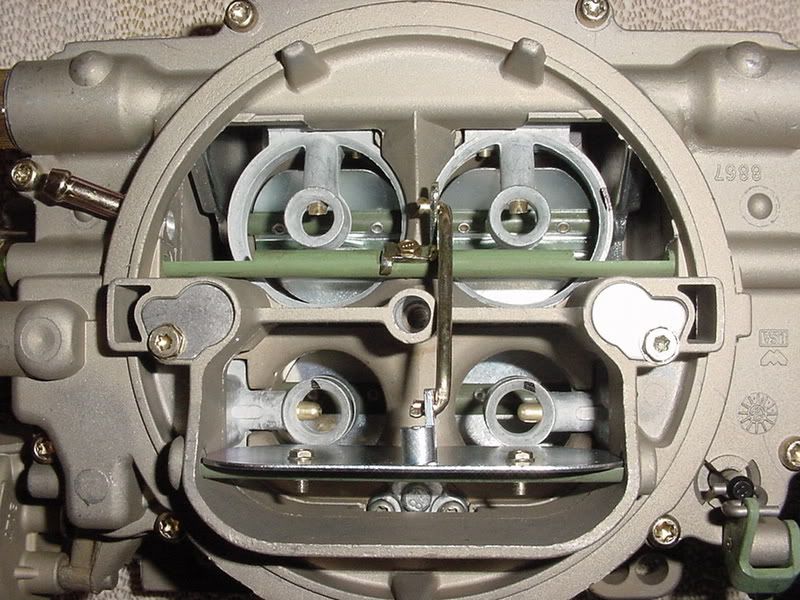

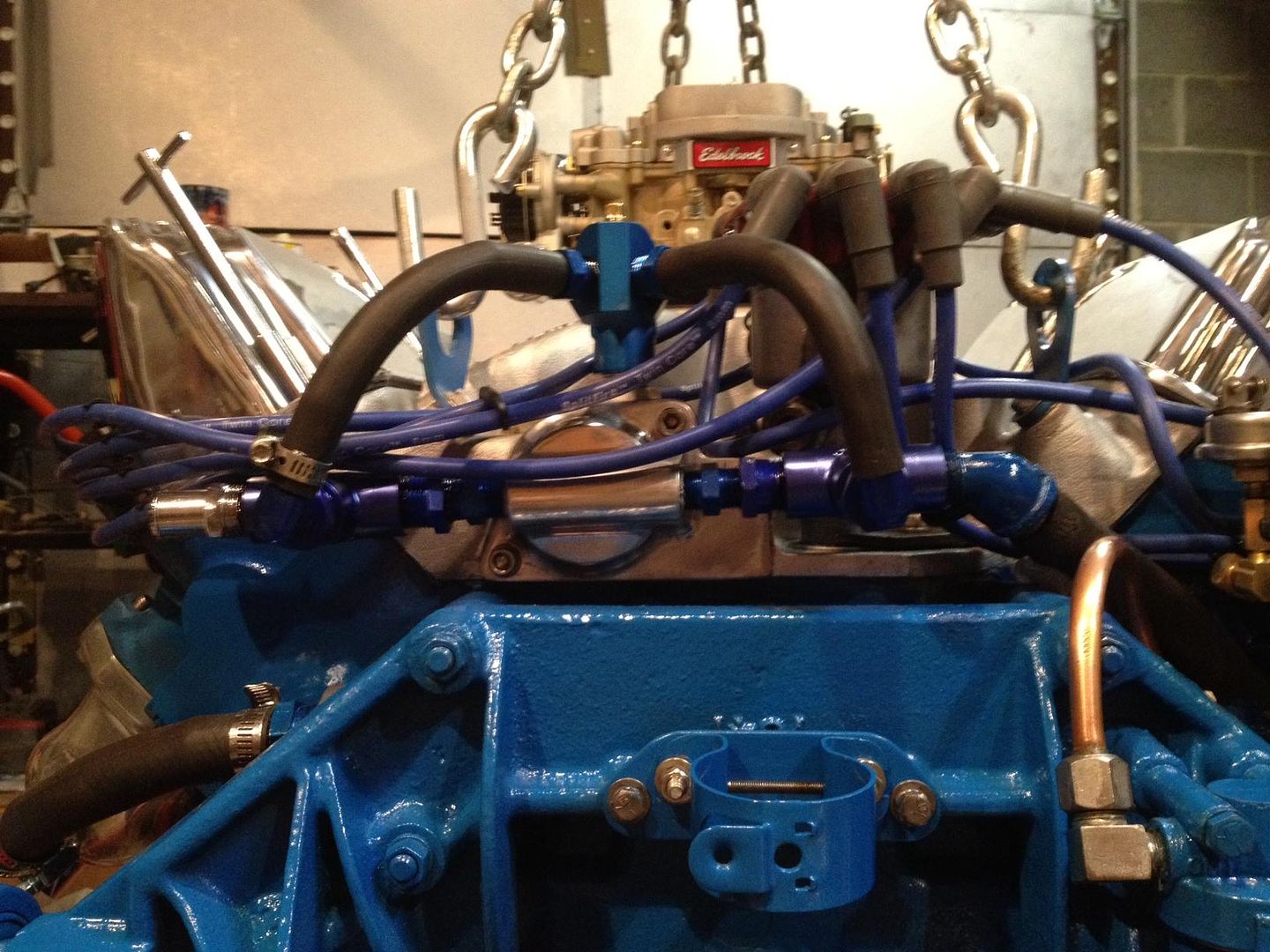

Here is what the stock Carter AFB with PCV system should look like (2 photos) on the Chris Craft 427 motors. Note the PCV system is just run right to the carb from the valve cover. The weight of the internal piston, along with a little spring pressure, keeps the valve closed at low rpm when idle and docking is important. Once you get up to speed, the valve opens and it sucks in all the fumes.....the make-up air goes in through the other valve cover vent.

And soon I will be able to have my own PCV system hooked up properly due to the uber-nice thread posted here complete with photos and drill bit sizes, etc.

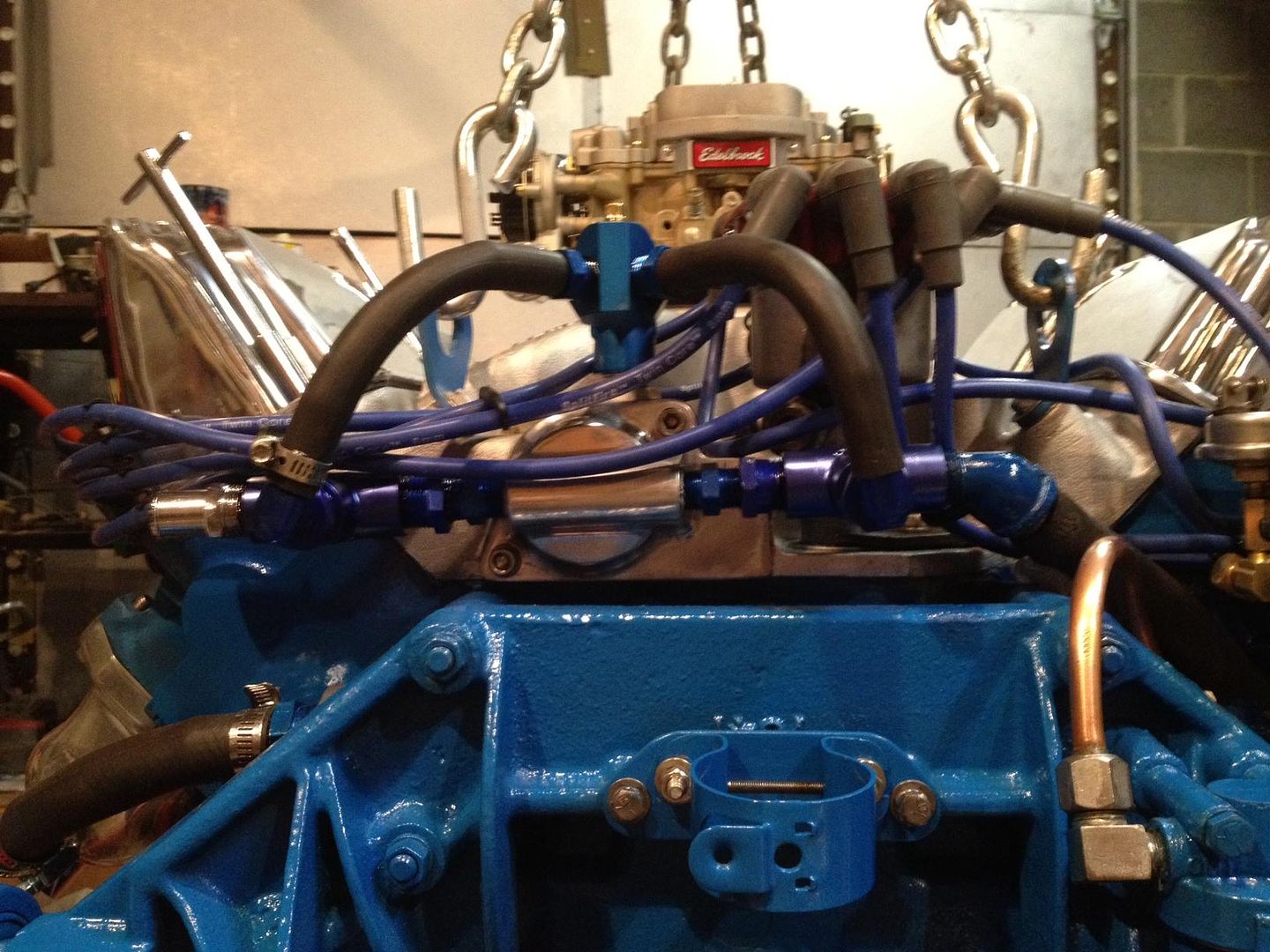

Here is the motor I am working on now, going in a 23 Lancer inboard.

I have received NUMEROUS reports that the 600 cfm #1409 works great on the 427 motors, and if you do the math or check the online carb calculators you'll see the 427 at 4000 rpm still has PLENTY of carb excess capacity with a 600 and there is no need to EVER go up to a 750 on a stock marine motor.* I will say that on my 20' Skiff, due to the tilt of the motor in that boat, I did need a wedge because the controls on a #1409 are partially regulated by weighted pieces that work with gravity.....the secondary did not want to kick in properly due to a ever-so slight physical contact with the linkage components, and the wedge solved the issue.

Thank you again for this very informative link here on MarineEngine.com about how to drill a #1409. I could not find it anywhere else, certainly not at Edelbrock! Here it is again for reference.

Maybe in the near future I will be able to supplement this with some photos of my own.

http://www.marineengine.com/boat-forum/showthread.php?252498-Edelbrock-1409-PVC-Fitting-Install

regards, happy boating all

Paul

I'm Paul from the ChrisCraftCommander.com web site and our membership frequently sources MarineEngine.com for help, so I would like to share some info back with you all here.

I have converted my 327F Chris Craft motor (on a 20' runabout, 1966 vintage) to the #1409 and it runs great. The 1409 is a 600 cfm carb and it is acutually thought of as "too big" for a 327, but in practice all I can say is the motor just runs great with it. Here are a couple photos.

This is what I started with, and now you can see why I wanted a new carb. The inside did not look any better.

The new #1409 sure looked a lot nicer inside, and I am glad I did not have to spend ANY time trying to rebuild that old carb.

In this photo above you can start to see an issue.* There is a crankcase breather on the left that will allow fumes to be sucked into the flame arrestor, but that tube on the right is connected to a PCV system and this carb won't accommodate this feature.* On the Carter AFB from which this new Weber built Edelbrock #1409 was cloned, there is a vac port especially FOR the PCV system.* In a PCV system if it is hooked up properly you can get the idle down nicely and if you pull the hose off the engine will speed up, and this shows that the PCV is working properly.*

So now just because it seems I need to do this before I forget...............here is some data from the Carter 625 for the record here.

Here are the specs on the original Chris Craft Carter AFB

Original Equipment Chris Craft Carter AFB specifications (427 Ford)

Carb ID number is 4157 S

This is a 625 CFM unit.

Primary jet is .1015

Secondary jet is .086

Metering Rods are two step, first step (power) is .055, and the

second (cruise rod) is .061

You can almost buy the exact same carb

from Carter, with improvements of course (hey, they have learned a

thing or two about carbs in the last 35 years, no longer use leather,

for instance). Edelbrock has a 600 CFM unit that matches up pretty close, but

Carter has a 625 marine which is even closer, but the jets on both of

these are a tad different than the ones selected for the 427 Ford..

By comparison, the (generic) marine Edelbrock 600

Primary jet: .098

Secondary: .101

Metering rods: .068 x .047

So I noticed there is a place to drill the #1409 to accept a PCV valve just like the ones on the original CC motors, and I found this marvelous thread here on the MarineEngine.com site with photos and specs how to do this.

http://www.marineengine.com/boat-forum/showthread.php?252498-Edelbrock-1409-PVC-Fitting-Install

This is a wonderful thread and I want to share it on my own web site to help people, with due reference back to this site of course.

So in any case today I called Edelbrock for some assistance (doing my homework, I didn't want to drill a $360 carb just yet without wondering if they had a PDF they could send me showing more info).**

Well I am disappointed today, got a guy in the carb tech department who thought the marine carb had a soft plug and all I had to do was pull it out.

When I politely advised him that due to his comment, it suggested he had not seen a #1409 marine carb lately, he decided to get some help.............then after two more holding patterns I finally got the "carb department supervisor".

This guy was polite and he deserves due credit for this. He offered nothing in the way of tech assistance or help, however.

He said "We sell about 3500 of these per year and we get about 3 calls per year on this subject".

He claimed the USCG would not allow them to build a carb with a pcv system port, and this may be true, but I am unwilling to argue the point. It seems a pcv system is

a requirement on an inboard engine, because we can not be dumping corrosive and explosive petroleum mist into an enclosed compartment like that.

Just putting a vent near the carb so it sucks in any fumes is a very poor substitute for an actual POSITIVE crankcase vent system.

The petroleum laden mist is caustic and it can even be explosive.

I mentioned that Edelbrock didn't drill the carb but they put a dimple there where it was supposed to be drilled, but they would not help a guy who wanted (and needed) to drill one to meet functional needs.

I got no sympathy (or help).

All I got was the company liability management chapter and verse.

He said his hands were tied due to the liability.

This may be true, but it is also a little sad.

We're basically on our own.

So in any case, the #1409 works just great on my 327F, I am installing one on a custom 427 FE now, and I plan to install two on my twin engine 427-powered 1966 38 Commander in the near future.

Here is a photo of the 327 running nicely, proof the 600 cfm carb works well on a small block motor.

Yeah it's running good but look at that home-made PCV system.

Here is what the stock Carter AFB with PCV system should look like (2 photos) on the Chris Craft 427 motors. Note the PCV system is just run right to the carb from the valve cover. The weight of the internal piston, along with a little spring pressure, keeps the valve closed at low rpm when idle and docking is important. Once you get up to speed, the valve opens and it sucks in all the fumes.....the make-up air goes in through the other valve cover vent.

And soon I will be able to have my own PCV system hooked up properly due to the uber-nice thread posted here complete with photos and drill bit sizes, etc.

Here is the motor I am working on now, going in a 23 Lancer inboard.

I have received NUMEROUS reports that the 600 cfm #1409 works great on the 427 motors, and if you do the math or check the online carb calculators you'll see the 427 at 4000 rpm still has PLENTY of carb excess capacity with a 600 and there is no need to EVER go up to a 750 on a stock marine motor.* I will say that on my 20' Skiff, due to the tilt of the motor in that boat, I did need a wedge because the controls on a #1409 are partially regulated by weighted pieces that work with gravity.....the secondary did not want to kick in properly due to a ever-so slight physical contact with the linkage components, and the wedge solved the issue.

Thank you again for this very informative link here on MarineEngine.com about how to drill a #1409. I could not find it anywhere else, certainly not at Edelbrock! Here it is again for reference.

Maybe in the near future I will be able to supplement this with some photos of my own.

http://www.marineengine.com/boat-forum/showthread.php?252498-Edelbrock-1409-PVC-Fitting-Install

regards, happy boating all

Paul

Last edited: