Ok guys, I thought I would start a new thread on this problem as the other one was getting kinda long. I got a break from the weather today and got some results for the tests you all recommended I do. First I did the vacuum test straight off the manifold at operating temp.....at around 700 RPM vacuum would flutter between 17 and 18, at 1000 it was 19, at 1500....23 with a slight flutter, at 2000 a steadier 23, at 2500 still 23, and at 3000 it dropped back to 22. If I punched it real quick and brought it back it dropped to about 12 then quickly returned to 23.

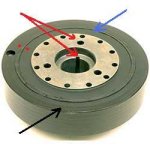

I put the timing index tape on and took the following readings....700 RPM-----10 deg., 1000 RPM----10 deg.,2000RPM----it advances 10 deg. for a total of 20 deg.,at 2500 RPM it advances 10 more deg. for a total of 30 deg.BTDC, at 3000 it's stays at the same 30 deg total advance and no matter how far I advance the engines the timing stays the same at 30 deg. BTDC.

Well, that's it guys I've done all you asked of me so far, I hope this helps you to help me, I have some doubts about the total advance on the timing, but I'll wait to hear what you all have to say. Thank you....Lee

I put the timing index tape on and took the following readings....700 RPM-----10 deg., 1000 RPM----10 deg.,2000RPM----it advances 10 deg. for a total of 20 deg.,at 2500 RPM it advances 10 more deg. for a total of 30 deg.BTDC, at 3000 it's stays at the same 30 deg total advance and no matter how far I advance the engines the timing stays the same at 30 deg. BTDC.

Well, that's it guys I've done all you asked of me so far, I hope this helps you to help me, I have some doubts about the total advance on the timing, but I'll wait to hear what you all have to say. Thank you....Lee