Boat is a 1988 Tiara 31 with Crusader 454s FWC, with approx 1500hrs used on Chesapeake Bay. Bought boat used with about 1100 hrs in 2006 and replaced elbows and risers in 2006.

Should I be looking at replacing them again as it is 5 years later? Started noticing a little more steam so thinking may be getting clogged.

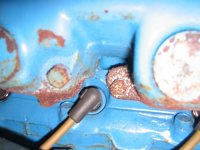

Also how do I detemrine if I need to replace the manifolds? They look OK but I have no idea as to age.

Thanks

Should I be looking at replacing them again as it is 5 years later? Started noticing a little more steam so thinking may be getting clogged.

Also how do I detemrine if I need to replace the manifolds? They look OK but I have no idea as to age.

Thanks