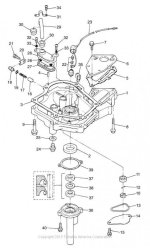

After replacing a worn impeller, re-assembly became impossible because the drive shaft won't insert all the way. I have tried everything I can think of.

This morning I tried to insert the drive shaft ONLY without even a bothering with the shift linkage clamp. I turned the lower unit 90 degrees so that only the drive shaft was inside the shaft housing and the lower shift rod was outside the housing. I inserted the drive shaft and, as usual, it encountered a hard bump. Whatever it bumps into forces the shift lever into the forward position so that the lever doesn't move even though the shift rod is not connected to the lower unit at all.

I have tried to insert the drive shaft with the shift lever in rear, neutral and forward, and same thing happens: the drive shaft pushes the shift lever forward and the system locks even before the drive shaft is fully seated. Something invisible in the linkage is making life miserable for me.

I thought reading online instructions and watching a video would make the project doable in not much time. Ouch. I am going to order a factory service manual, obviously, but I would appreciate some help getting the system back together in the meantime.

This morning I tried to insert the drive shaft ONLY without even a bothering with the shift linkage clamp. I turned the lower unit 90 degrees so that only the drive shaft was inside the shaft housing and the lower shift rod was outside the housing. I inserted the drive shaft and, as usual, it encountered a hard bump. Whatever it bumps into forces the shift lever into the forward position so that the lever doesn't move even though the shift rod is not connected to the lower unit at all.

I have tried to insert the drive shaft with the shift lever in rear, neutral and forward, and same thing happens: the drive shaft pushes the shift lever forward and the system locks even before the drive shaft is fully seated. Something invisible in the linkage is making life miserable for me.

I thought reading online instructions and watching a video would make the project doable in not much time. Ouch. I am going to order a factory service manual, obviously, but I would appreciate some help getting the system back together in the meantime.