Okay guys, I am at my wits end here. I have a 1998 Force 90hp motor.

Was stalling under load sporadically so I took it in to shop. Mechanic found that water was getting in bottom 2 cylinders and we went through first and replaced all major gaskets, then eventually found a hairline crack in block and replaced power head and rebuilt carbs to ensure warranty. Problem is, that did not fix the stalling under load issue, it actually made it worse.

Was doing it 1-2 time in a day. Now it does it every time I stop and fish a bit. Of course it did not fail when mechanic took it to the lake. Weird thing is i can start it great first thing. run all over and it runs great. I can start and stop no problem, but if I wait 20 minutes or so, then try to go it dies when I give it gas.

Now, if i hit the choke (key) while giving gas, it sputters then goes. If I throw the throttle down hard, sometimes it will go to. If I slowly throttle up it dies. This leads me to believe it is fuel related rather than electrical, but who knows

So to date, the following things have been done by either me or the mechanic (in no particular order).

Any body have any ideas as I am tired of taking it to the mechanic.

Was stalling under load sporadically so I took it in to shop. Mechanic found that water was getting in bottom 2 cylinders and we went through first and replaced all major gaskets, then eventually found a hairline crack in block and replaced power head and rebuilt carbs to ensure warranty. Problem is, that did not fix the stalling under load issue, it actually made it worse.

Was doing it 1-2 time in a day. Now it does it every time I stop and fish a bit. Of course it did not fail when mechanic took it to the lake. Weird thing is i can start it great first thing. run all over and it runs great. I can start and stop no problem, but if I wait 20 minutes or so, then try to go it dies when I give it gas.

Now, if i hit the choke (key) while giving gas, it sputters then goes. If I throw the throttle down hard, sometimes it will go to. If I slowly throttle up it dies. This leads me to believe it is fuel related rather than electrical, but who knows

So to date, the following things have been done by either me or the mechanic (in no particular order).

- new powerhead

- all new engine gaskets

- new fuel pump

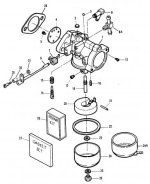

- full carb rebuild

- new primer bulb

- new fuel filter

- checked vent screen on gas cap

- cleaned screen on fuel pick up in tank

Any body have any ideas as I am tired of taking it to the mechanic.