Hi Guys,

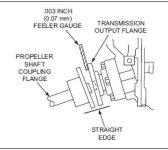

I'm working on a V drive boat (non Crusader). It's a big Block Chevy, and I need some advice on aligning the V drive flange to the propshaft coupler flange. There are two mounts on the engine and two on the V drive. There is a fair amount of movement in the propshaft: left to right and up and down. The engine mounts are decent and the cutlass bearing is tight. I would like some basic advice on how to perform an alignment on this setup. I suppose it is not much different in practice than a straight inboard but the access is really tight. I would like to get it right on the first try. Any advice would be greatly appreciated.

Thanks,

Jon Allen

I'm working on a V drive boat (non Crusader). It's a big Block Chevy, and I need some advice on aligning the V drive flange to the propshaft coupler flange. There are two mounts on the engine and two on the V drive. There is a fair amount of movement in the propshaft: left to right and up and down. The engine mounts are decent and the cutlass bearing is tight. I would like some basic advice on how to perform an alignment on this setup. I suppose it is not much different in practice than a straight inboard but the access is really tight. I would like to get it right on the first try. Any advice would be greatly appreciated.

Thanks,

Jon Allen