norm_edwards

Member

Hello Jeff and all, nice day to be alive.

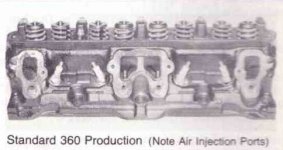

Can you guys please help me id what sort of head I have here. The machine shop put them on with the wrong gaskets, I have found the right ones, but I am interested in figuring this out. I can't find a reference to these lower holes.

It has been a ridiculous exercise in futility that carries on...the same port engine that has now been rebuilt twice by the same shop under warranty will not time.

We have tripled checked everything, if we time it to the marks we can't run it lower than 1000 rpm without it stumbling and stalling. I have had two very good mechanics look at it and they are 95% certain the shop has the cam out of position by a tooth or two.

The water will not circulate with the t-stat in. Checked the t-stat and it opens fine, with it in the water is being blown out the overflow tube on the expansion tank and it seems to be disappearing internally someplace, but we have found no water in the plugs, nor leaks below?

The worst part is I wanted to pay to dyno them before they went back in, but the shop had built them completely and said I would void my warranty if I disassembled the manifolds etc. to put them on the dyno.

Cheers!

Norm

Can you guys please help me id what sort of head I have here. The machine shop put them on with the wrong gaskets, I have found the right ones, but I am interested in figuring this out. I can't find a reference to these lower holes.

It has been a ridiculous exercise in futility that carries on...the same port engine that has now been rebuilt twice by the same shop under warranty will not time.

We have tripled checked everything, if we time it to the marks we can't run it lower than 1000 rpm without it stumbling and stalling. I have had two very good mechanics look at it and they are 95% certain the shop has the cam out of position by a tooth or two.

The water will not circulate with the t-stat in. Checked the t-stat and it opens fine, with it in the water is being blown out the overflow tube on the expansion tank and it seems to be disappearing internally someplace, but we have found no water in the plugs, nor leaks below?

The worst part is I wanted to pay to dyno them before they went back in, but the shop had built them completely and said I would void my warranty if I disassembled the manifolds etc. to put them on the dyno.

Cheers!

Norm