am_dew

Advanced Contributor

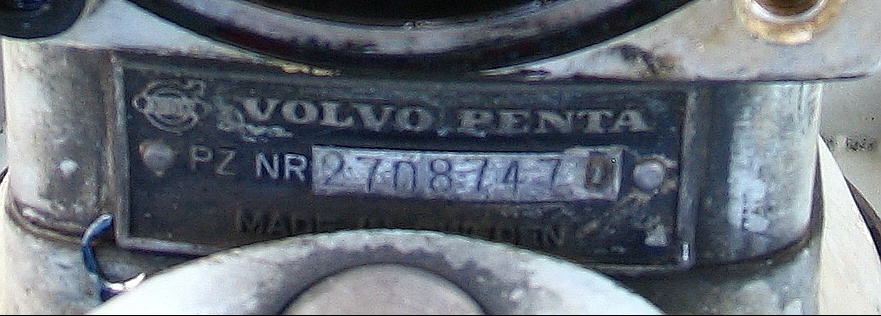

My 270D outdrive (standard prop shaft) has never had a line cutter so I decided to buy one this winter since I have had a few problems with weeds getting wrapped around the prop area. Today I put it on but when I put the prop on over it, I noticed right away that the prop shaft did not protrude enough from the prop hub to be able to place the tabbed lock washer. I removed the prop and line cutter and took a closer look. Turns out that there was a ~3/4 inch metal spacer on the prop shaft right against the anode. I removed the spacer and put the line cutter and prop back on and then the prop shaft protruded from the prop the same distance as if the spacer was there. So, it seems the line cutter serves the same purpose (and more I hope) as the spacer I removed.

My real question is this...is it correct that the large round portion of the line cutter is right up against the anode? I imagined it would be different for some reason...that there would be a larger gap between the disc portion of the line cutter and the anode.

My real question is this...is it correct that the large round portion of the line cutter is right up against the anode? I imagined it would be different for some reason...that there would be a larger gap between the disc portion of the line cutter and the anode.