sandkicker

Outstanding Contributor

OK, so after killing a lot of time (per other topic) trying to find an up to date P/N for this part, I just drove the 40 mins to the shop I use for parts and asked them to look it up and sell me one. That's when the fun started.

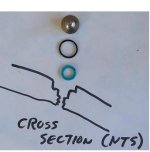

They handed me an O ring, one where the OD of the O ring was about the same as the screw head, but the thickness was about 0.0625". Everytime I've replaced this seal, the dealer sold me one type or another of a washer type seal... the last time ( 09) made of some sort of elastomer with one side smooth and the other side with two distinct ridges. I had him double check the number and that's what its "supposed" to be. I don't like thin O rings that don't sit in a groove to stabilize them when installed.

So... what's it supposed to be... washer style or O-ring?

They handed me an O ring, one where the OD of the O ring was about the same as the screw head, but the thickness was about 0.0625". Everytime I've replaced this seal, the dealer sold me one type or another of a washer type seal... the last time ( 09) made of some sort of elastomer with one side smooth and the other side with two distinct ridges. I had him double check the number and that's what its "supposed" to be. I don't like thin O rings that don't sit in a groove to stabilize them when installed.

So... what's it supposed to be... washer style or O-ring?