"Hello,

Md7a is running great

"Hello,

Md7a is running great up until now.

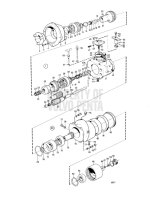

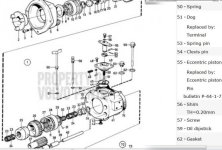

Transmission will not go in to neutral while engine is running. Will shift to neutral while engine is off and stays in neutral with intermittent movement of prop shaft after starting engine.

I have removed control cable to trouble shoot.

Idle's at 800 rpm

Discovered the transmission leaks oil

Level got low, topped off.

I have the overhaul instruction manual and a parts catalog. Prices for parts at Marine Parts are shocking.

Has anyone had this problem and fixed it?

Time for a repower?

Thanks,

John"

Md7a is running great

"Hello,

Md7a is running great up until now.

Transmission will not go in to neutral while engine is running. Will shift to neutral while engine is off and stays in neutral with intermittent movement of prop shaft after starting engine.

I have removed control cable to trouble shoot.

Idle's at 800 rpm

Discovered the transmission leaks oil

Level got low, topped off.

I have the overhaul instruction manual and a parts catalog. Prices for parts at Marine Parts are shocking.

Has anyone had this problem and fixed it?

Time for a repower?

Thanks,

John"