Too many people out there thinking they can apply their automobile engine knowledge to a marine engine.

Some aspects will cross over! The Key is in knowing which will and which will NOT!

These things are designed to be under constant heavy load. The more you open the throttle, the more the load and it never lets up. With a car yes, you put a lot of stress on it when accelerating but once you're up to speed, the horsepower demand falls off a lot.

Precisely!

The answer for marine power is displacement. The bigger the engine, the more stress it can handle. Attempting to increase power with higher compression, high lift cams, is the exact opposite of what you should do.

No disagreement there!

So, to solve your buddy's problem, he should rebuild it as close to factory stock as possible,

I completely disagree with that.

GM uses the full dished pistons in their alleged Marine Engines due to the bean counters!

One piston fits all 8 bores, they are inexpensive to produce, and the guy installing them onto the connecting rods can be drunk while doing so.

No engineer in his right mind would spec out this piston for a true SBC Marine Engine!

Once again, the bean counters win over that of the engineers.

I would encourage you to read a few articles by Jeff Smith, Dennis Moore, Larry Carley and/or John Erb (chief engineer for KB Performance Pistons) regarding SBC combustion chamber design.

Granted, most of their articles have been written for automotive use, yet the basics can be easily applied to the SBC Marine version.

If he wants it to go faster, his future must have big blocks in it.

No where in this thread do I read where the OP's friend wants to go faster.

He wants to avoid detonation.

And let's not forget that this all comes with a higher fuel consumption hit.

A well built SBC, with the correct pistons, will offer slightly better fuel economy.

Again, stock is best.

If regarding the SBC, completely disagree with that statement!

I would again encourage anyone to educate themselves regarding SBC marine load detonation, what causes it and what the marine industry does to combat it while sacrificing torque.

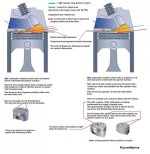

This image should make it very clear as to the quench/squish effect, and as to why the GM full dished piston doesn't work as well.

The Q/E build also greatly reduces the likelihood of detonation.

Look closely and carefully at the black dotted lines that represent the dished area of the piston deck.

Now contrast that with the cylinder head's quench surface!

On the left side, this is the undesirable area where the gasses are given a place to hide, of which leads to a greater potential for detonation.

On the right side, these gasses are not given an area to hide, of which greatly reduces the potential for detonation.

With this build, ignition TA can be increased some, therefor making for a better LPCP.

With this build, ignition TA can be increased some, therefor making for a better LPCP.

It's all about LPCP occurring where it needs to be!