Hello,

I'm working on a 1989 8 HP Mercury 2 Stroke that has no spark.

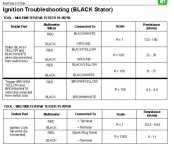

I haven't been able to find out what readings I'm looking for on the coil, stator, or trigger assembly for this motor. Keep in mind these reading are made while the parts are still on the motor. If I need to remove them to make the readings let me know.

Left Coil

Between Positive and Negative Terminals - 0.1 Ohm

Between Positive and Spark Plug Wire - 903 Ohms

Between Negative Spark Plug Wire - 904 Ohms

Right Coil

Between Positive and Negative Terminals - 0.1 Ohm

Between Positive and Spark Plug Wire - 972 Ohms

Between Negative Spark Plug Wire - 973 Ohms

Stator

Between the wires - 3.121k Ohms

Between blk/ylw and ground - 3.257 Ohms

Between blk/wht and ground - 135.7 Ohms

Trigger Assembly

Between the wires - 735

Between brwn/ylw and ground - Nothing

Between brwn/wht and ground - Nothing

Are these readings any good?

I read somewhere I could test the kill switches or kill switch wires, but the instructions were unclear. If anyone can guide me on how to work the wires in order to test the kill switches let me know.

I also read it could be the switch box, but there are zero instructions on how to test the switch box. Anyone know how to go about testing the switch box?

Also, is there anything else I can test for?

I'm working on a 1989 8 HP Mercury 2 Stroke that has no spark.

I haven't been able to find out what readings I'm looking for on the coil, stator, or trigger assembly for this motor. Keep in mind these reading are made while the parts are still on the motor. If I need to remove them to make the readings let me know.

Left Coil

Between Positive and Negative Terminals - 0.1 Ohm

Between Positive and Spark Plug Wire - 903 Ohms

Between Negative Spark Plug Wire - 904 Ohms

Right Coil

Between Positive and Negative Terminals - 0.1 Ohm

Between Positive and Spark Plug Wire - 972 Ohms

Between Negative Spark Plug Wire - 973 Ohms

Stator

Between the wires - 3.121k Ohms

Between blk/ylw and ground - 3.257 Ohms

Between blk/wht and ground - 135.7 Ohms

Trigger Assembly

Between the wires - 735

Between brwn/ylw and ground - Nothing

Between brwn/wht and ground - Nothing

Are these readings any good?

I read somewhere I could test the kill switches or kill switch wires, but the instructions were unclear. If anyone can guide me on how to work the wires in order to test the kill switches let me know.

I also read it could be the switch box, but there are zero instructions on how to test the switch box. Anyone know how to go about testing the switch box?

Also, is there anything else I can test for?