Hi- I recently got a B100S outboard 10hp 1983 model year. When I got it there was no water coming out the pee hole, so I replaced the impeller, which didn't work, so I replaced the T-stat and cleaned a bunch of gunk from the intake manifold. I blew air through the holes in the block. Put it back together and water came out nicely. Let it run for awhile in the tank and the water never got hot, but I figured it was fine. Compression tested both cylinders at 100psi (which seems a little low).

Took it out ran it for awhile, seemed fine. Then running under WOT it suddenly stops. I needed to avoid a barge so I got it started and motored off, it stopped again and I noticed some burning oil and the motor was really hot like it was overheating. At no time did the water stop coming out of the pee hole. Limped home and found the inside of the case covered in oil! Not sure where it was leaking from, maybe the cap or the plastic housing that holds the cap. Also noticed that the lower cylinder was leaking oil from the spark plug hole.

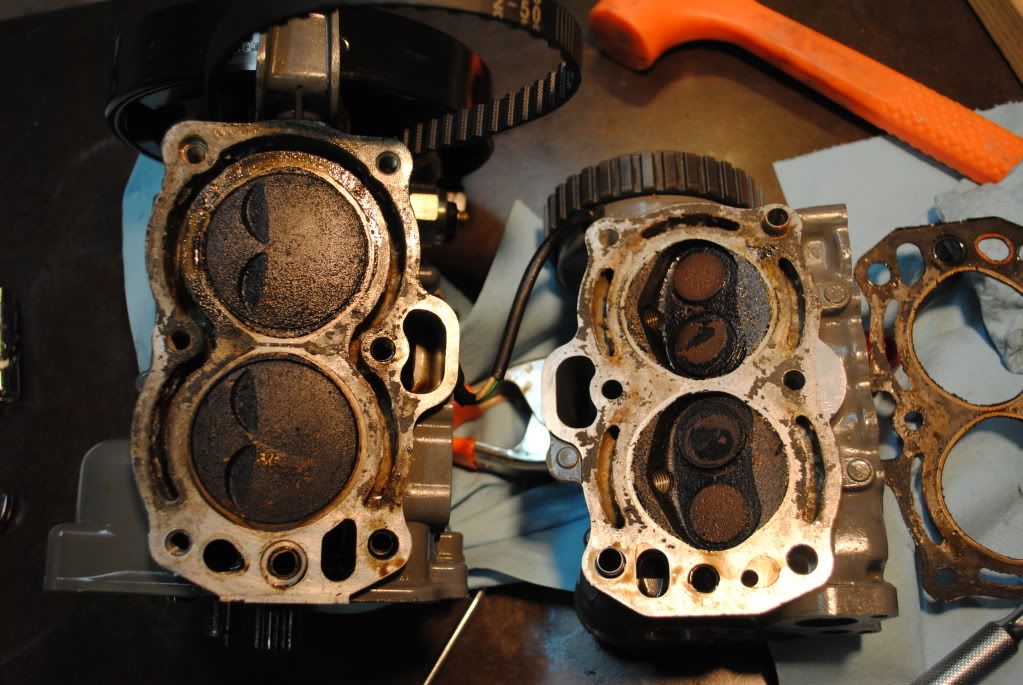

So I disassembled the engine thinking I had not cleaned the block out well enough. As I am taking it apart I find a wasp nest plugging the oil breather tube (unfortunately I found this out after I removed the block from the oil pan). Could this be the source of my overheating problem? Or is there gunk still in the block (I blasted hi pressure water through all cooling holes in the block and they seemed to pass water fine). Did I ruin the engine? Do i need to replace the head gasket or did the overpressure oil come through the rings? I don't have the tools to take it apart any further (can't get the flywheel off or the valves back in place I don't think). I have the shop manual and the Seloc manual but they don't mention this scenario!

Any advice would be much appreciated!

Thanks,

BigD14

Took it out ran it for awhile, seemed fine. Then running under WOT it suddenly stops. I needed to avoid a barge so I got it started and motored off, it stopped again and I noticed some burning oil and the motor was really hot like it was overheating. At no time did the water stop coming out of the pee hole. Limped home and found the inside of the case covered in oil! Not sure where it was leaking from, maybe the cap or the plastic housing that holds the cap. Also noticed that the lower cylinder was leaking oil from the spark plug hole.

So I disassembled the engine thinking I had not cleaned the block out well enough. As I am taking it apart I find a wasp nest plugging the oil breather tube (unfortunately I found this out after I removed the block from the oil pan). Could this be the source of my overheating problem? Or is there gunk still in the block (I blasted hi pressure water through all cooling holes in the block and they seemed to pass water fine). Did I ruin the engine? Do i need to replace the head gasket or did the overpressure oil come through the rings? I don't have the tools to take it apart any further (can't get the flywheel off or the valves back in place I don't think). I have the shop manual and the Seloc manual but they don't mention this scenario!

Any advice would be much appreciated!

Thanks,

BigD14